When you shop high-quality hot glue sticks, you’re investing in the success of your crafting projects. The difference between cheap and premium glue sticks becomes obvious the moment you start working – good ones flow smoothly, bond strongly, and don’t leave you frustrated with stringy messes or weak connections. Quality glue sticks contain better polymers and additives that ensure consistent performance, whether you’re working on delicate scrapbooking projects or heavy-duty repairs.

What Makes Hot Glue Sticks Actually Good

The secret lies in the polymer blend. High-quality sticks use ethylene-vinyl acetate (EVA) copolymers with specific melt flow rates that work perfectly with your glue gun’s heating element. Cheaper sticks often contain more filler materials like calcium carbonate, which makes them flow poorly and creates weak bonds.

Temperature compatibility matters more than most people realize. Professional-grade sticks are formulated for specific temperature ranges – usually low-temp (250°F), high-temp (380°F), or dual-temp varieties. Using the wrong temperature stick in your gun creates all sorts of problems, from poor adhesion to dangerous overheating.

Size and Diameter Precision

This might sound boring, but stick diameter consistency is huge for reliable feeding. Quality manufacturers maintain strict tolerances – usually within 0.1mm. When sticks vary too much in width, they jam in the gun’s feed mechanism or create gaps that let air in, causing those annoying air bubbles in your glue lines.

Length matters for different reasons. Longer sticks (10-12 inches) reduce the frequency of reloading, which keeps your workflow smooth and maintains consistent temperature. Short sticks from budget brands often leave you constantly stopping to reload, which cools down the gun and affects bond strength.

Reading the Technical Specs

Open time is probably the most important spec nobody talks about. This tells you how long you have to position your materials before the glue sets. Quality sticks typically offer 10-15 seconds of working time, while cheap ones might give you only 3-5 seconds. That difference can make or break detailed work.

Viscosity ratings indicate how thick the melted glue will be. Lower viscosity works better for porous materials like fabric or paper, while higher viscosity is perfect for non-porous surfaces like metal or plastic. Good manufacturers actually list these numbers on their packaging.

Testing Bond Strength

Here’s something I learned from a furniture repair expert: quality hot glue should hold at least 15 pounds per square inch when properly applied. You can test this yourself by gluing two pieces of wood together and hanging weight from them after the glue cures completely.

The bond should also handle temperature cycling. Cheap glue becomes brittle in cold weather and softens too much in heat. Quality formulations maintain flexibility across a wider temperature range, typically from -40°F to 200°F.

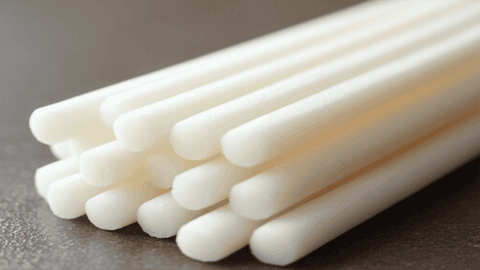

Color and Transparency Clues

Clear sticks aren’t automatically better, but they do tell you something about the manufacturing process. Truly clear sticks require better quality control and purer raw materials. Colored sticks can be excellent too, but watch out for streaky or cloudy coloring, which often indicates inconsistent mixing during production.

Amber or yellowish tints in “clear” sticks usually mean the manufacturer used recycled materials or lower-grade polymers. While these might work fine for basic projects, they’re not ideal when you need reliable, long-lasting bonds.

Storage and Shelf Life Considerations

Even the best glue sticks degrade over time, especially in humid environments. Quality sticks typically maintain their properties for 2-3 years when stored properly, while cheap ones might start getting brittle or developing surface oxidation within months. Look for packaging that includes manufacturing dates or batch codes – this shows the manufacturer cares about quality control and traceability.