Table of Contents

- Cured-In-Place Pipe (CIPP) Lining

- Pipe Bursting

- Robotic Inspections and Repairs

- Environmental Benefits of Trenchless Repairs

Key Takeaways

- Non-invasive sewer repair methods reduce disruption and environmental impact.

- Techniques such as Cured-In-Place Pipe (CIPP) lining and pipe bursting provide efficient solutions.

- Robotic technologies enhance precision in inspections and repairs.

- Smart monitoring systems enable proactive maintenance.

Introduction

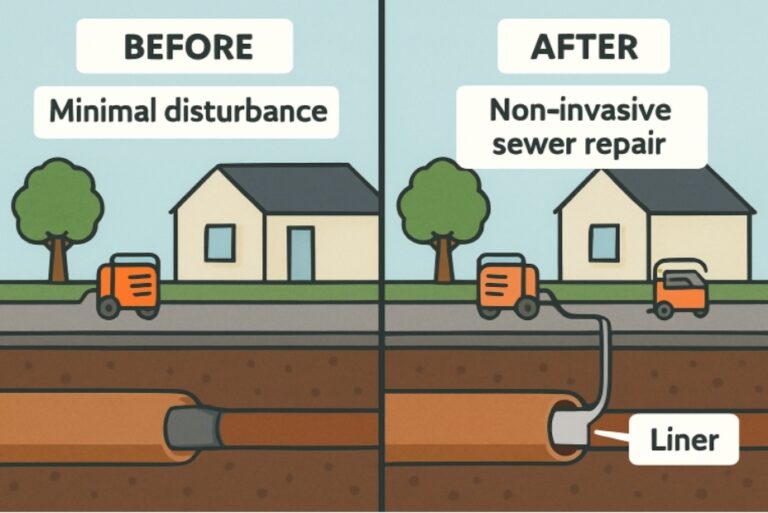

Urban infrastructure relies heavily on efficient and reliable sewer systems, yet traditional repair operations can profoundly disrupt daily life. Open trench excavations, lengthy road closures, and disturbed landscapes were once the norm for addressing sewer issues. Now, modern non-invasive techniques are redefining how municipalities and contractors approach the challenge of repairing underground pipes with minimal impact. Homeowners and cities alike are turning to innovative solutions, such as trenchless sewer service Salt Lake City, to resolve their sewer issues quietly, quickly, and with considerably less environmental impact. These advanced approaches help secure long-term reliability while prioritizing community convenience and sustainability.

Utilizing state-of-the-art equipment and strategic planning, today’s non-invasive sewer repair options can effectively resolve most underground damage and blockages. A shift towards trenchless techniques helps mitigate noise, dust, and disruption while also supporting responsible stewardship of urban green spaces and roadways. This article examines the latest industry advancements and highlights why both residents and municipal planners benefit from adopting modern sewer repair technologies.

Cured-In-Place Pipe (CIPP) Lining

CIPP lining is a transformative technology in the realm of trenchless sewer repairs. The process begins with inserting a flexible liner, saturated with resin, into the failing pipe. Once properly positioned, the liner is exposed to heat or ultraviolet light, initiating a curing process that bonds the resin to form a new, robust pipe within the original structure. This seamless solution eliminates leaks, restores flow capacity, and significantly extends the pipe’s working life without requiring street or yard excavation.

One of the principal benefits of CIPP lining is its versatility: it can rehabilitate pipes of various shapes and diameters while seamlessly handling sharp bends or offsets. The process is quick, often taking just a day, making it highly attractive for neighborhoods and businesses seeking to avoid lengthy utility disruptions. CIPP lining has proven particularly beneficial for aging urban infrastructure, reducing repair costs and limiting surface damage.

Pipe Bursting

When sewer pipes are severely damaged, collapsed, or composed of materials beyond repair, pipe bursting offers an efficient replacement alternative. This technique employs a specialized bursting head that is inserted into the existing pipeline. As the head is pulled through, it fragments the old piping outward into the surrounding soil while simultaneously pulling a strong, new pipe behind it. The end result is a completely new, durable pipeline occupying the exact footprint of the original—without the need for extended trenching.

Pipe bursting is ideal for upgrading to larger-diameter pipes to accommodate increased flow or switching to more durable materials, such as high-density polyethylene (HDPE). This approach is commonly used to modernize outdated clay or cast iron pipes found in older districts, making the utility system more reliable for future generations. Additionally, pipe bursting is cost-effective due to lower labor requirements, reduced restoration expenses, and rapid project completion.

Robotic Inspections and Repairs

The marriage of robotics and sewer repair has revolutionized system assessments and real-time diagnostics. Small, remotely operated vehicles equipped with high-resolution cameras, lights, and a suite of environmental sensors can now traverse the most confined pipelines. These robots not only deliver clear, visual records of pipe conditions but can also measure and record data about cracks, blockages, and pipe wall integrity with impressive precision.

Advanced robotic devices are now capable of conducting minor repairs within the pipe itself. Tasks such as cutting away intruding tree roots, applying resin patches, or removing localized debris can be performed remotely, eliminating the need for human entry. These capabilities enhance worker safety, reduce downtime, and pave the way for a more preventive approach to pipeline management. Information gathered from robotic inspections can be stored and analyzed for strategic maintenance planning, ensuring issues are addressed well before they escalate into emergencies.

Environmental Benefits of Trenchless Repairs

Non-invasive trenchless repair techniques are not only efficient, but they are also environmentally responsible. Reducing excavation means less soil disruption, preservation of mature trees, and minimal alteration to established green spaces or roads. The reduction in heavy machinery usage leads to noticeably lower noise pollution and smaller carbon emissions.

Trenchless methods also minimize waste generation by rehabilitating existing pipes instead of sending large volumes of debris to the landfill. The advanced materials used—such as cured epoxy resins and modern plastic piping—typically outlast their traditional counterparts, reducing the need for frequent repairs and lessening the overall environmental impact of sewer system upkeep.

Ultimately, adopting trenchless and non-invasive repair strategies aligns sewer maintenance with broader sustainability goals, conserves urban ecosystems, supports local health, and delivers cost savings throughout the infrastructure life cycle.